Macro-etching is used to reveal the heterogeneity of metals and alloys. Macro-etching is used extensively for quality control in the steel industry as it provides information on variations in:

Macro-etching is used to reveal the heterogeneity of metals and alloys. Macro-etching is used extensively for quality control in the steel industry as it provides information on variations in:

• Structure, such as grain size, flow lines, columnar structure, dendrites,

• Variations in chemical composition as evidenced by segregation, carbide and ferrite banding, coring, inclusions, and depth of carburization or decarburization.

The many applications of macro-etching in the fabrication of metals are the study of weld structure, definition of weld penetration, dilution of filler metal by base metals, entrapment of flux, porosity, and cracks in weld and heat affected zones, etc.

Nusatek has extensive experienced and competent personnel who perform macro etch examination on welding joint especially for Welding Procedure Qualification Test and Welder Qualification Test.

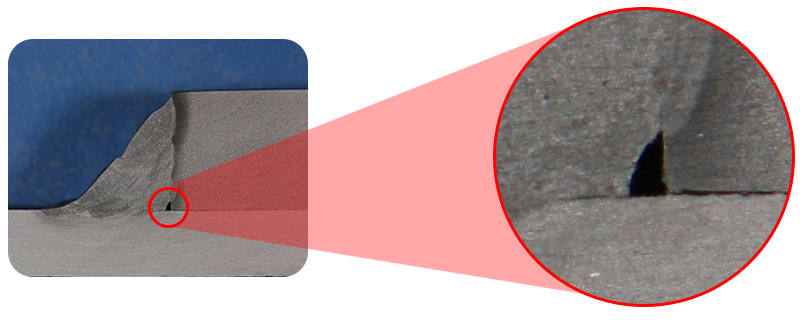

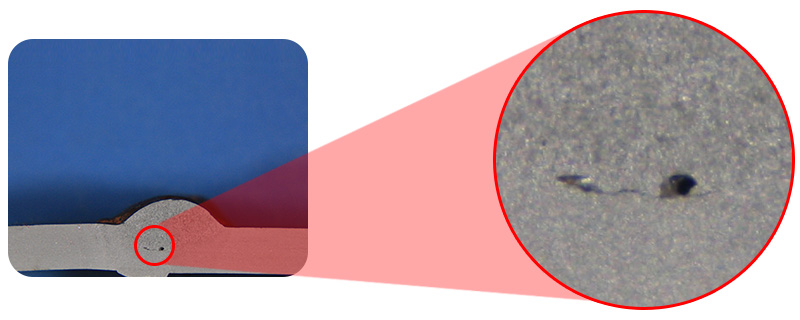

The test procedure involves the welded joint being cut transversely and the specimen is polished, etched and examined. The macro structure is evaluated with the naked eye or under low (up to 20x) magnification. This testing is an excellent method in determining the soundness of weld metal by revealing the metallurgical structure produced by the weld such as lack of penetration, lack of fusion, cracking and inclusions.

Standards/specifications

• BS EN ISO 9606-1 : 2013

• BS 4515-1 : 2009

• BS 4515-2 : 1999

• AS 1210 : 2010

• AS/NZS 3992 : 2000

• ASME IX : 2015

Read More

Polishing and Etching

Samples are polished across their cross-section using abrasive paper of up to P600 and then etched using some type of mild acid mixture, dependent on the base material used. The acid etch provides a clear visual appearance of the internal structure of the weld.

The etchant is usually applied at room temperature using cotton swab. In some cases, the material need to use electrolyte etch to reveal the structure. The etching process will continue until the weld structure clearly produced. After the surface is etched completely, it is washed with clean water and dried. The tester must be careful not to touch the etched surface when handling the specimen.

Features detected:

Weld soundness

Lack of penetration

Slag inclusions

Lack of fusion

Cracking

Porosity

Macro Determination and Measurement Using Stereo Microscope

Nusatek offers our customers with superior quality macro determination and measurement by using stereo microscopes. The test samples can be measured accurately and precisely by our expert team. This expertise is widely demanded and appreciated for its vast usage in determining welding penetration test, HAZ depth measurement, tube to tubesheet, and etc. Our service meets international quality standards and help customers improve product performance as well as work processes. Nusatek provides this type of testing to various industries, for example on automotive parts, thermite welded parts and cooling system components.

Standards/specifications

- ASME IX

- British Standard

- Australian Standard

- MMC-ES-X87010

- DTSH 5603G

- TIS

- Client’s Requirement

Main usage is as follows:

- Throat length

- Leg length

- Leak path (tubesheet)

- Root of penetration (tubesheet& fillet)

- Weld reinforcement

- Penetration size